Working

title

Revelation

Aim

of the project

The

original intention was to extend semester 1, fabrication and

construction's exploration into claritas and the human form.

Conceptually this work is exploring the foundation of the christian,

jewish and muslim faith, and its relevance.

Focus

on the titanic battle between good and evil for the souls of

humanity.

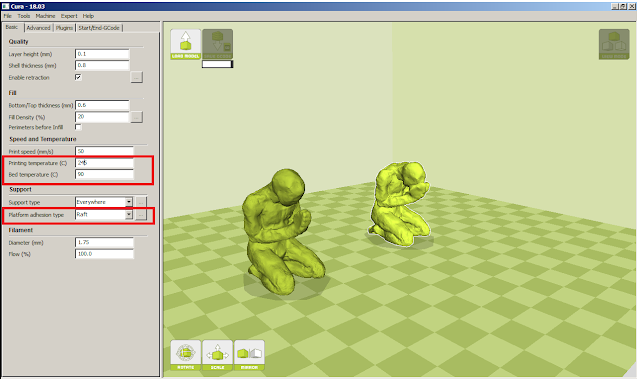

This

was explored through the creation of a set of figures are displayed

in the configuration of a game board. These figures were 3d printed

using glow in the dark filament.

The

intention was to create a set of figures of two types, one praying

man and one crying man. The intention with the human form

itself was to to reduce the form down to its basic components.

I am interested in the generalities not the particularities of the

individual to create that connection to the self.

This

work is intended to be installed in the white room at QCA on a small,

low plinth in the configuration of a game that is 'in play'.

The

key to this installation is not the figures themselves but the

installation.

consideration

for the installation and recording process are:

the

work is discussing the titanic battle for the souls of humanity

(within christian, islamic and judism context)

the

'game' is in play

the

board is not needed, as a discussion to our perception of this game,

we are unable to see the board

the

game is not chess or checkers, the rules of this game is unknown to

the viewer. We can project a set of rules such as the aformentioned

games but they may not apply.

in

recording a low camera angle which puts the viewer in the action as

opposed to being a spectator, in presentation of the installation it

is displayed from a low height, to put the installation into 'perspective'.

Theoretical

Framework

What

is the issue you are addressing in the work? What was the motivation

for doing the work?

The

work is an essoteric discussion on the foundation of judism,

islam and christianity, which keeping in mind that these faiths make

up over 50% of the worlds population (Adherents.com

) makes this a relevant contemporary issue. This discussion focuses on the titanic battle for our soul. This verison serves to discuss

from an analytical point of view, acting as a reminder that , as a

christian, we are involved in this game every day. That we cannot see

the board in play and our role with in it. We could be any of these

pieces.

Studio

Methodology

How

did you create the work and was process important in its creation and

why?

The

intention was two create two figures, this was achieved through the

physical creation, scanning and digital manipulation of the

praying man figure. The second figure , the crying man,

was created purely through the digital manipulation of the first.

The

figures were printed with ABS luminescent filament.

For

these prints a layer height of 0.2 was used. This greatly reduces print time (almost 50% less) and gave the forms a textured, almost

shimmery surface, which supports my conceptual focus of the soul and

claritas.

The

process of using 3d printing relates back to scripture , 'made in his

image' (Genisis 1:27), this is particularly important in regards to

the praying man. With the original form being Molded from air drying

clay which relates to Isaiah 64:8.

The

crying man was

digitally manipulated which relates back to the original sin,

knowledge.

Context

Compare

and contrast your work with two other practitioners in

the field who have similar aims to yours and support your conceptual

ideas.

In my research two artists were integral to the resolved work Amanda Parer and Alberto Giacometti.

Amanda

Parer challenges the notion of scale through her enchanting pieces

that explore the environment and the role of human beings in it.

And tries to

communicate this by using light and dark, humour and drama.

Her usage of glowing figures has been emulated within my own work but

myuse of scale explores our disconnection to the environment and the

connection between the viewer and artwork.

The

other key artistic influence was Alberto Giacometti's Walking man, the stylised male figure, with no individualised aspects, conveys the human condition. I chose retain some detail of the human

form but removed all identifyable facial features and minimised the

details of the hand. This process was a step in the direction to

abstract the human form to a minimum of information to convey a

'humaness'. This process of abstraction has been furthered for my

studio major.

Conclusion

How

is your work performing against your aims and theoretical framework?

Do

you have any evidence for this?

I feel that the use use of luminescent filament was successful in exploring the concept of claritas, tho i feel that for future projects the possiblility of increasing the intensity of the light will strengthen the aesthetic presence of the pieces. Conceptually the work is distanced and didactical in approach, which is a technique that I intend minimise in my practice now that it has been explored.

To extend on this project in the future my

intention is to upscale the idea of the gameboard with a shift of

conceptual focus to the participants place within this game. The

figures will be replaced with the participants and the gameboard will

become visible